JOY MACHINERY (SHANGHAI) CO., LTD.

VSD OIL-FREE WATER LUBRICATED SCREW AIR COMPRESSOR

JOY MACHINERY (SHANGHAI) CO., LTD.

VSD OIL-FREE WATER LUBRICATED SCREW AIR COMPRESSOR

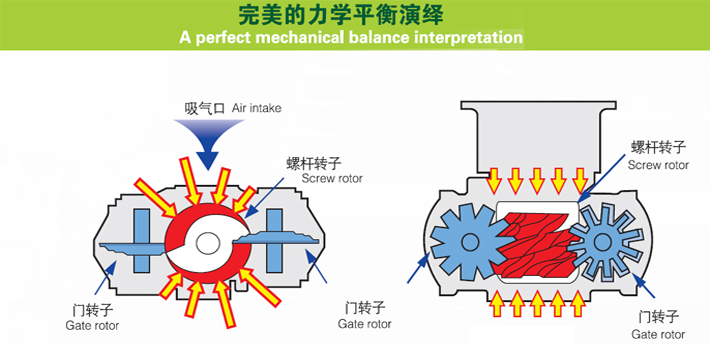

1. The fifth-generation oil-free screw air end technology is adopted, and the compressor air end and system are made of stainless steel alloy, realizing the technological transcendence from copper air end to stainless steel air end;

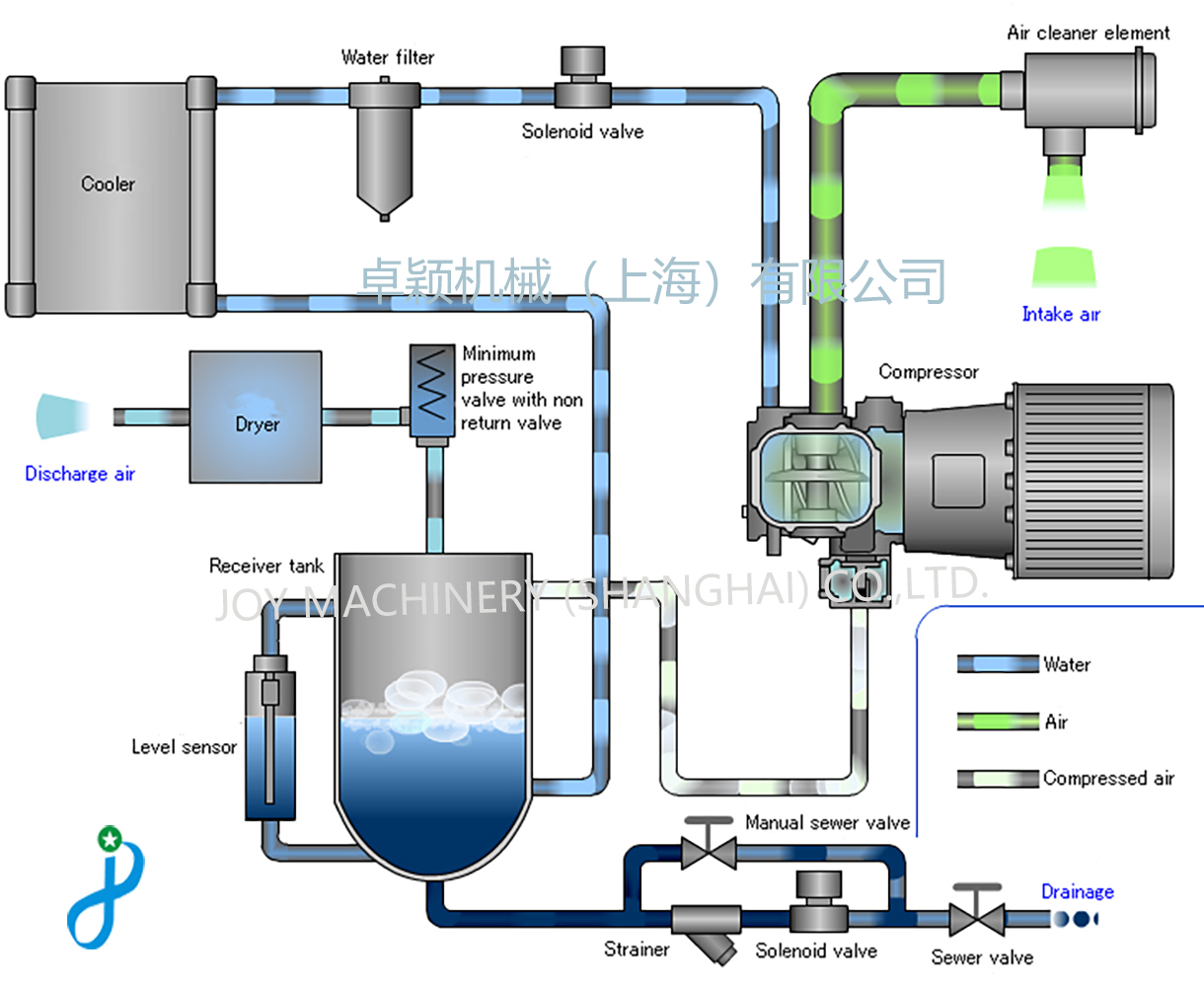

2. The world's advanced oil-free water-lubricated screw compression technology is adopted, and water is used as the medium for compression, sealing and cooling. The use cost is low, and the exhaust temperature of the air compressor is lower;

3. Through advanced sealing isolation technology, the compressed air is cleaner, which can produce 100% pure oil-free compressed air;

4. Higher volumetric efficiency and more energy saving, more than 15% energy saving than secondary dry twin screw oil-free air compressors, and more than 36% energy saving than first-level dry twin screw oil-free air compressors;

5. Wider pressure ranges: 2 bar - 40 bar;

6. The whole machine adopts integrated design, very few wearing parts, less failure points, more stable operation and long service life;

7. Routine maintenance, generally only changing the water filter and air filter, saves time and effort, and the maintenance cost is extremely low;

8. There is no lubricating oil for cooling and sealing, there is no oil stains in the surrounding environment of the entire air compressor, and the surrounding environment is greatly improved.

Application scope of piston air compressor, air compressor and screw air compressor | |

Air compressors are one kind of common power equipment. In simple terms, it is a device that compresses air to generate potential energy. Therefore, it has a wide range of applications. The common applications mainly include the following industries: | |

Mine | Air for ventilation, drilling large holes, removing water with compressed air, filtering fines, pneumatic hoist, driving rock drilling rigs, pneumatic drilling, blowing holes, piling machines, rock drilling machines, etc. |

Factory | Air jet cleaning, driven tools (steam hammers, concrete shakers, drills, grinders, cranes, paving breakers, riveting guns, descaling, pipe reels, wrenches), sandblasting, metallization, painting, water spray systems |

Sheet metal | Stirring solutions, transporting chips, jet cleaning, driving packaging presses, driving platen chuck clutches and positioners, air tools, finishing hammers, air picks, drills, grinders, hoists and lifters, combination tools, riveters, Sand blasting, lubricant spraying, paint spraying, container leak detection |

Forging | Blown oxide surface, furnace door air curtain, hoist and lift, drive bending and straightening machine, drive clutch brake and clamping device, drive forging hammer, fuel burner |

Casting | Hot metal truck positioning, cleaning equipment, conveying sand, driving pneumatic tools, sanding machines, grinding machines, hoists and lifts, air picks, tamping machines, steel brushes, sandblasting, sand screening, mud blasting cores |

Quarry | Lifting and handling materials, rock drilling rigs, gas supply, drilling and blasting machines, rock drilling machines, hand drills, water pumps |

Rubber industry | Cleaning of moulds and machinery, air lift, demolding, mould opening, pneumatic control, spraying |

Textile industry | Mixing liquids, air lifts, wetting, running accumulators, spraying liquids, spraying systems, infusions |

Chemical fiber | Gas for instrumentation, gas for silk suction gun and power source for printing and dyeing, etc. |

Cement | Storage ventilation, cement slurry mixing, cement bag cleaning and sealing, raw material mixing, dump truck, cleaning equipment, clinker cooling, cement and coal conveying, cement kiln cleaning, vehicle and ship loading and unloading, lifting and hoisting, pneumatic control |

Chemical | Aeration and agitation, separation tower gas, cleaning equipment, combustion gas, conveying, lifting liquid, spraying, cleaning pipeline, pneumatic control, process gas, conveying liquid |

Thermal power | Instrumentation, desulfurization and denitrification, blowing and cleaning pipes, bag dust removal, blowing off soot, cleaning boiler and condenser pipes, jet cleaning, transferring pulverized coal, removing sewage, pneumatic control, auxiliary equipment control, coal-fired transportation, industrial Water treatment equipment, etc. |

Hydropower | Engine control, lock maintenance, drive controller, drive lubrication pump, drive lock, start control, cleaning garbage net |

Beverage | Bottle washing machines, canning machines, interior spraying of wine barrels, gas for the food industry |

Food | Stirring liquid, gas (oxygen) for fermentation tank, cleaning equipment with nozzle, cleaning container with nozzle, material conveying, material filling, fermentation, food dehydration, filtration |

Glass industry | Blowing bottles and glassware, blowing lamps and electron tubes, supporting combustion of glass liquid, transferring raw materials, glass etching, clearing and drilling, conveying glass, pneumatic control, vacuum hanging plate, purging of residual material in the oil gun, cooling and cooling of the gun body, Bag dust removal and filter cartridge backflushing. |

Steel | Stirring solution, gas for deoxidation, gas for high-level converter, positioning of charging car, drilling of sediment chamber, unloading bag, cleaning of open-hearth furnace flue, driving clutch and brake, driving furnace door, driving charging and conveying device, driving lubrication system, Drives pneumatic tools, picks, grinders, hoists and lifts, sandblasting, blast furnace blasting, vacuum degassing |

Wood and furniture | Jet cleaning, air hoisting, impregnated wood, bending and straightening, clamping and clamping, pneumatic tools, engraving tools, drilling rigs, polishing machines, sanding machines, sandblasting, painting, water spraying |

Refinery | Combustion gases, draining and cleaning oil circuits, hoisting and hoisting, drive control systems, catalyst recirculation, sandblasting, painting |

Paper | Air cleaning equipment, hoists and lifts, pool anti-icing, roll feeding, pressed paper products, drive clutches, drive paper breakers, feed through machines, pneumatic controls, head case pressurization, head case removal, waste paper removal , vacuum drying |

Pharmaceutical | Stirring liquids, gas (oxygen) for fermentation of antibiotics, conveying raw materials, mixing and stirring raw materials, driving centrifuges, pneumatic control, jet pulverization, spray drying, transferring liquids, vacuum drying, vaporization and instrument gas |

Plastic | Cleaning of jet equipment, casting blanks, inflation of air objects for molding, inflation into tubes during extrusion, vacuum or pressure molding, cylinder operation |

Printing | Stir the solution, pack paper, lift |

Injection mold | Air assisted injection molding |

Metallurgical | Metal smelting, sintering, cold rolling, hot rolling, bundling and packaging of wire rods and sheets, production lines for continuous casting and rolling, etc. |

3D printing | Base room waste heat, particle, powder purge |

Military | Packaging of explosives, automatic control devices of torpedoes, automation equipment of ships, equipment purging, instrument gas, power execution and other operations. |

Tobacco | It is also used in power execution equipment such as wire injection machines, cigarette rolls, splicing and packaging, as well as instruments and equipment cleaning. |

Medical chamber | Supply and exhaust (oxygen) systems for air pressurized chambers and pure oxygen pressurized chambers |

Automobile | Spray Washing Machines, Drive Assembly Tools, Lifting, Pneumatic Controls, Tire Inflation, Forging Shops, Foundry Shops, Sheet Metal Shops |

Aircraft | Blasting machines, stripping, driving assembly tools, drilling rigs, steam hammers, hoists, combination tools, reamers, riveting guns, screwdrivers, forging hammers, metal forming presses, sandblasting, painting |

Aerospace | The rocket is purged with high-pressure nitrogen, and the oil-free high-pressure chamber is purged. In the aerospace industry, in addition to being able to withstand irradiation and high temperature, pneumatic devices can also withstand large acceleration speeds, so they have been widely used in the control of modern aircraft, rockets and missiles. |

JOY MACHINERY (SHANGHAI) CO., LTD.

VSD OIL-FREE WATER LUBRICATED SCREW AIR COMPRESSOR

Model | Air Capacity | Pressure | Power | Noise | Dimension(mm) | Outlet | Weight | |

N.m3/min | Mpa | KW | HP | DB | Length*Width*Height | KG | ||

JMW-5.5A/W | 0.72 | 0.8 | 5.5 | 7.5 | 57±2 | 800*800*1200 | 3/4" | 430 |

0.65 | 1.0 | |||||||

JMW-7.5A/W | 1.05 | 0.8 | 7.5 | 10 | 57±2 | 800*800*1200 | 3/4" | 470 |

0.80 | 1.0 | |||||||

JMW-11A/W | 1.72 | 0.8 | 11 | 15 | 60±2 | 1200*855*1335 | 3/4" | 580 |

1.42 | 1.0 | |||||||

JMW-15A/W | 2.25 | 0.8 | 15 | 20 | 60±2 | 1200*855*1335 | 3/4" | 620 |

1.92 | 1.0 | |||||||

JMW-18.5A/W | 3.00 | 0.8 | 18.5 | 25 | 63±2 | 1400*1010*1340 | 1" | 680 |

2.20 | 1.0 | |||||||

JMW-22A/W | 3.65 | 0.8 | 22 | 30 | 63±2 | 1400*1010*1340 | 1" | 730 |

3.00 | 1.0 | |||||||

JMW-30A/W | 5.00 | 0.8 | 30 | 40 | 66±2 | 1650*1180*1505(A) | 1 1/4" | 1100 |

3.90 | 1.0 | |||||||

JMW-37A/W | 6.30 | 0.8 | 37 | 50 | 66±2 | 1650*1180*1505(A) | 1 1/4" | 1150 |

5.33 | 1.0 | |||||||

JMW-45A/W | 7.80 | 0.8 | 45 | 60 | 68±2 | 2050*1300*1758(A) | 2" | 1390 |

6.30 | 1.0 | |||||||

JMW-55A/W | 10.10 | 0.8 | 55 | 75 | 69±2 | 2150*1360*1758(A) | 2" | 1470 |

7.90 | 1.0 | |||||||

JMW-75W | 13.00 | 0.8 | 75 | 100 | 74±2 | 1800*1300*1750 | 2" | 1650 |

11.80 | 1.0 | |||||||

JMW-90W | 15.00 | 0.8 | 90 | 120 | 74±2 | 2200*1550*1800 | 2" | 2350 |

13.00 | 1.0 | |||||||

JMW-110W | 20.20 | 0.8 | 110 | 150 | 77±2 | 2200*1550*1800 | DN65 | 2480 |

16.66 | 1.0 | |||||||

JMW-132W | 23.52 | 0.8 | 132 | 180 | 77±2 | 2200*1550*1800 | DN65 | 2550 |

19.97 | 1.0 | |||||||

JMW-160W | 28.11 | 0.8 | 160 | 220 | 79±2 | 2200*1550*1800 | DN80 | 3600 |

25.45 | 1.0 | |||||||

JMW-185W | 31.32 | 0.8 | 185 | 250 | 79±2 | 3000*1800*2100 | DN80 | 3800 |

29.00 | 1.0 | |||||||

JMW-250W | 45.00 | 0.8 | 250 | 340 | 80±2 | 3100*2250*2200 | DN100 | 4500 |

40.00 | 1 | |||||||