Cleaning and maintenance methods for screw air compressors

(1/3)

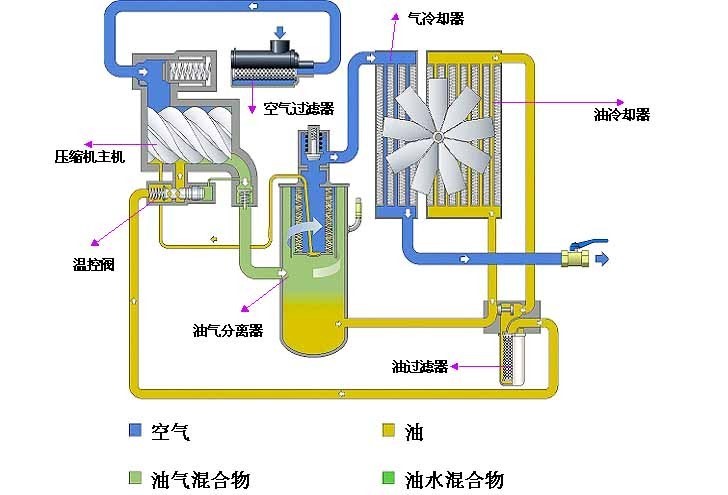

The working environment of air compressors in practical applications is often complex, with dust, oil stains, various particulate matter, and floating objects. Over time, the compressor may accumulate oil stains, carbon deposits, sediment, rust, and other debris. Air compressors that have been lubricated with different brands of oil may also produce asphalt like black glue, which can cause the machine head to lock and be scrapped in severe cases. Therefore, it is necessary to regularly clean the air compressor, including the machine head, paint bucket, radiator, oil pipe interior, and various valves, in order to eliminate safety hazards.

1. Whole machine cleaning

The method of online cleaning: First, run the air compressor for a few minutes until the engine oil reaches room temperature;

Turn off the air compressor, wait for the internal pressure to be released, open the oil cap, pour in the compressor line carbon cleaning agent, and tighten the oil cap;

Start the air compressor and run it for about 30 minutes, with a maximum online cleaning time of 80 hours;

Drain the old engine oil and then add new engine oil.

The temperature of the air compressor after general cleaning will decrease by about 8-10 ℃.

2. Cooling unit cleaning

In China, the coolers of air compressors are generally divided into two types: air-cooled and water-cooled, so there are different cleaning methods for different coolers.

2.1 Air cooled cooler

(1) Open the air duct cover to clean the cover, or remove the cooling fan;

(2) Blow down the dirt with compressed air and then remove the dirt from the air guide cover; If it is dirty, spray some degreaser before blowing. When the screw air compressor cannot be cleaned by the above methods, the cooler needs to be removed, soaked or sprayed with carbon cleaning agent, and cleaned with a brush (wire brush is strictly prohibited).

(3) Install the cover plate or cooling fan properly

2.2 Water cooled cooler

Open the cooling water inlet and outlet pipes.

Inject air compressor scale cleaning agent for soaking or use a pump to circulate and flush (with better backwashing effect).

Rinse with clean water.

Install the cooling water inlet and outlet pipes.

When the scaling of the oil cooler is severe and the above methods are not ideal for cleaning, the oil cooler can be removed separately, the two end caps can be opened, and a special cleaning steel brush or other tool can be used to remove the scale. When cleaning the medium side of the cooler cannot effectively reduce the temperature, it is necessary to clean the oil side. The method is as follows:

Open the inlet and outlet oil pipes; Inject cleaning solution for soaking or use a pump for circulating flushing (with better backwashing effect);

Rinse with clean water;

Blow dry with dry air or remove water with dehydrated oil;

Install the inlet and outlet oil pipes.

3. Clean the water vapor separator

The structure of the water gas separator in a screw air compressor is similar to that of an oil and gas tank. The inlet is designed against the wall, forming a solid centrifugal force. Due to the weight factor of water and gas, it can effectively separate moisture from compressed air.

Cleaning of water vapor separator: Remove the cover of the water vapor separator and soak it in cleaning agent for cleaning.

JOY MACHINERY always adheres to the corporate vision of "building a leading brand of oil-free air compressors in the world", and hopes to provide high-quality, clean and safe air for food, beverage and other production enterprises on the road of oil-free air compressor research and development, production and sales. Source protection, and also contribute a little bit to people's health and safety.

JOY MACHINERY oil-free air compressor series is widely used in the food and beverage processing industry due to its clean air source and continuous and stable gas transmission. If you have any needs, please contact us! JOY Machinery (Shanghai) Co., Ltd. has a professional design team with rich experience and welcomes customization. Diversified products can meet most applications and meet your one-stop shopping needs. The air compressor series includes power frequency screw air compressors, variable frequency screw air compressors, permanent magnet variable frequency screw air compressors, two-stage compression screw air compressors, integrated screw air compressors, laser cutting air compressors, medium and high pressure air compressors. Air compressors, oil-free water-lubricated screw air compressors (special oil-free screw air compressors for the medical industry), diesel-moving screw air compressors, electric-moving screw air compressors and other products.

"Customer satisfaction is our unswerving pursuit", "High quality, good services", and strive to make every customer use the good products they like.

For more information about our products, please visit us at : www.shairbuild.com, 24-hour hotline: 13621925718 (WeChat, WhatsApp).