With the development of society and the improvement of technology, the equipment we use is also quietly changing. This article introduces the changes in cutting technology. The editor of JOY Machinery (Shanghai) Co., Ltd. will introduce it to you as follows:

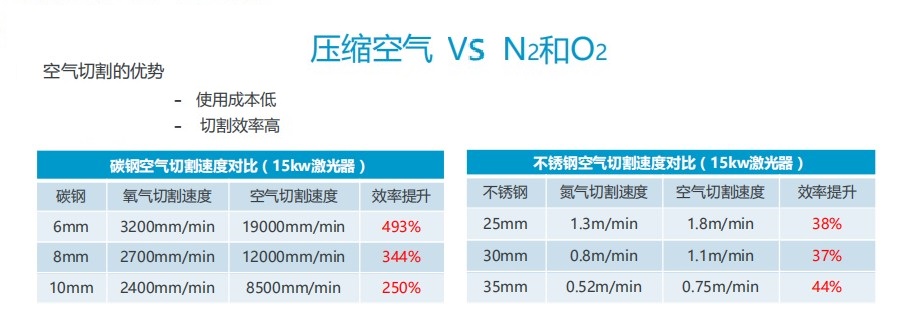

In the past, the technology of this cutting equipment was mainly monopolized by foreign companies, and the domestic purchase of equipment was expensive. Some use liquid nitrogen or liquid oxygen for cutting, but for ordinary small and medium-sized enterprises, the use of these two is also very expensive, so the popularity is relatively not good. With the advancement of technology, laser cutting technology is favored by everyone. Laser cutting machines are mainly used to cut steel plates. With the maturity of domestic laser cutting machinery and equipment, air compressors are gradually used for cutting. The price has an advantage, and more and more users can use high-quality and low-cost products.

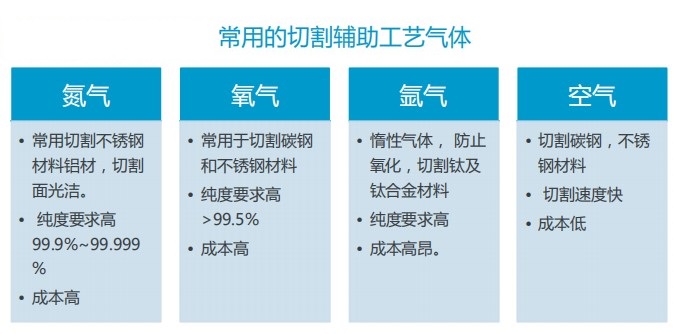

Laser cutting machine is a new type of machine that uses laser beams for cutting. Compared with the traditional stamping process, which is easy to deform the object, it has made great progress, so it is more and more favored by everyone, but when the laser cutting machine is used, gas is used. The thickness of the cut item has a lot to do with the choice of gas. So what gas does the laser cutting machine use? Generally, the air compressed by the air compressor is mostly used.

So what kind of air compressor should be used? The selection of the air compressor mainly depends on the power of the laser cutting machine and the thickness of the cutting steel plate. Generally speaking, one 1KW laser cutting machine can use one 7.5 or 11KW screw air compressor, and one 1.5KW laser cutting machine can use one 11KW or 15KW air compressor. The selected pressure is generally 13bar. If you need to cut more thick steel plates, 16bar air compressors are generally selected. Of course, the laser cutting equipment provider needs to provide data.

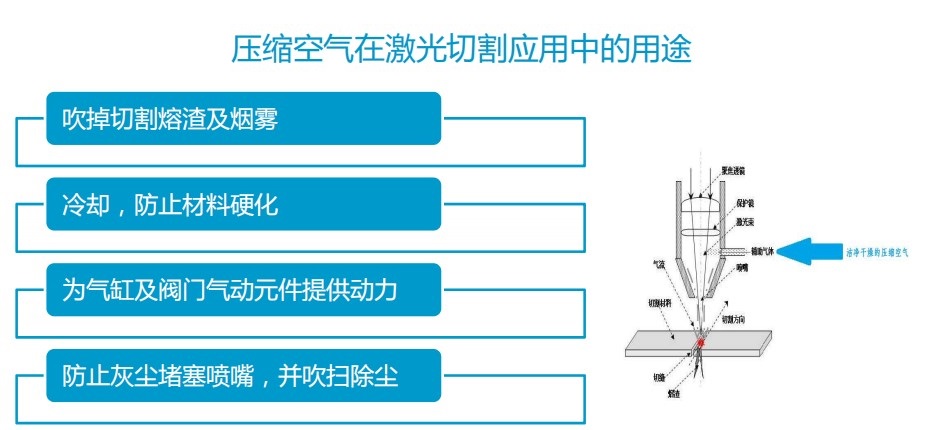

The purification system of the post-processing of the air compressor is also particularly important for the laser cutting machine. Once the compressed air contains a large amount of water and oil, the damage to the laser cutting machine is quite large, especially the lens of the laser cutting machine, maybe because the moisture and oil content in the compressed air leads to frequent replacement of lenses, which affects production and increases the cost of purchasing lenses. Therefore, when purchasing an air compressor, buy a set of drying equipment with better quality and filters, and there are quite a few necessary, although the purchase cost has increased, it will reduce the damage rate of the cutting machine lens due to the quality of the compressed air, so overall the use cost will be lower.

For the processing of steel plates with small thickness, JOY Machinery specially designs an integrated air compressor for laser cutting.