How to choose an air compressor for nitrogen production using a nitrogen production mechanism?

Nitrogen (N2) is a odourless and colorless gas. In standard air, nitrogen accounts for 78.08%, while oxygen only accounts for 21%, and there are also small amounts of other gases.

What is the function of nitrogen?

Nitrogen is widely used in various industries. For example: electronic chip industry, laser cutting, food preservation, grain depots, chemicals, petrochemicals, lithium batteries, semiconductors, pharmaceuticals, and so on.

When there is a small demand for nitrogen, purchasing is an efficient choice. In the face of industrial production needs, an air compressor system and a nitrogen generator can be used to produce nitrogen on-site. The purity, pressure, and amount of nitrogen can also be controlled, making it a more reliable choice.

The working principle of on-site nitrogen production is to separate nitrogen molecules from oxygen molecules in compressed air, thereby obtaining a pure nitrogen supply. The commonly used techniques include PSA (pressure swing adsorption) method and membrane separation method.

How to produce nitrogen on-site?

1. PSA pressure swing adsorption nitrogen production

Using carbon molecular sieves as adsorbents, oxygen molecules can pass through the sieve pores due to their smaller size than nitrogen molecules, while nitrogen molecules cannot pass through the sieve pores, allowing users to obtain the required purity of nitrogen.

2. Membrane separation for nitrogen production

Under a certain pressure, gases with different properties such as oxygen and nitrogen have different permeation rates in the membrane to separate oxygen and nitrogen. Suitable for small and medium-sized nitrogen users with nitrogen purity ≤ 98%.

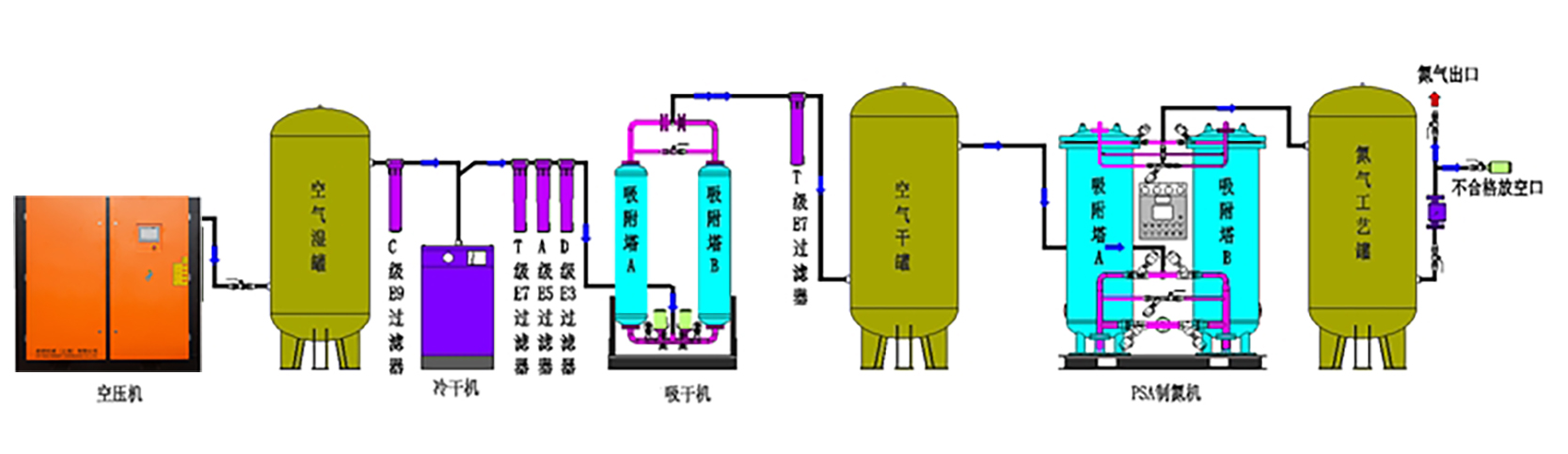

Process flow diagram of pressure swing adsorption nitrogen production device

PSA air separation nitrogen production is a direct production of nitrogen from air through pressurized adsorption and atmospheric desorption. The entire equipment consists of an air compressor (air compressor), compressed air filtration system, PSA nitrogen production host, automatic control system, and nitrogen storage tank.

The air compressor is the power source of compressed air in the nitrogen production system, which is related to the performance and stable operation of the entire nitrogen production system. Therefore, the selection of an air compressor is very important.

The performance of the nitrogen production supporting air compressor is optimized as an oil-free air compressor. Of course, a micro oil screw air compressor can also be used, but it needs to be equipped with post-treatment and precision filters.

When selecting an air compressor, it is necessary to first understand the flow rate, purity, pressure, dew point and other parameters of the nitrogen generator. The selected air compressor flow rate must be greater than the finished nitrogen flow rate.

Nitrogen accounts for about 78% of the air, and there is a 3% pressure loss from compressed air to the nitrogen generator. The oil content of compressed air is less than 0.003ppm, and the pressure is between 0.70MPa-1.2MPa. Considering the pressure loss in actual production, it is recommended to configure the pressure above 0.8MPa.

For example, how large an air compressor should be equipped for a 100 cubic meter nitrogen generator per hour? 100 ÷ 78% ÷ 97% ≈ 132 (cubic meters/hour) X3 times=396 cubic meters/hour

Whether you are adding a new nitrogen production room or renovating a nitrogen production room, JOY Machinery tailors aerodynamic solutions for nitrogen industry enterprises, and is installed and debugged by a professional installation and after-sales team.

JOY MACHINERY always adheres to the corporate vision of "building a leading brand of oil-free air compressors in the world", and hopes to provide high-quality, clean and safe air for food, beverage and other production enterprises on the road of oil-free air compressor research and development, production and sales. Source protection, and also contribute a little bit to people's health and safety.

JOY MACHINERY oil-free air compressor series is widely used in the food and beverage processing industry due to its clean air source and continuous and stable gas transmission. If you have any needs, please contact us! JOY Machinery (Shanghai) Co., Ltd. has a professional design team with rich experience and welcomes customization. Diversified products can meet most applications and meet your one-stop shopping needs. The air compressor series includes power frequency screw air compressors, variable frequency screw air compressors, permanent magnet variable frequency screw air compressors, two-stage compression screw air compressors, integrated screw air compressors, laser cutting air compressors, medium and high pressure air compressors. Air compressors, oil-free water-lubricated screw air compressors (special oil-free screw air compressors for the medical industry), diesel-moving screw air compressors, electric-moving screw air compressors and other products.

"Customer satisfaction is our unswerving pursuit", "High quality, good services", and strive to make every customer use the good products they like.

For more information about our products, please visit us at : www.sh-joymachinery.com; www.shairbuild.com , 24-hour hotline: 0086 13621925718 (WeChat, WhatsApp).