Oil-free air compressor classification

At present, the most widely used air compressor is the oil injection type. However, due to the adhesiveness of the air compressor oil, most oil filter equipment cannot completely remove the air compressor oil, which cannot meet the requirements of certain industries such as the pharmaceutical industry and the chemical industry. The demand for pure compressed air in the mining industry and the electronic industry, so oil-free air compressors came into being.

There are many types of oil-free air compressors. Generally, oil-free air compressors are roughly divided into: screw oil-free air compressors, centrifugal oil-free air compressors, piston oil-free air compressors and scroll oil-free air compressors, etc. , each air compressor has its own characteristics and advantages, and its scope of application is also different. The following will introduce them one by one:

Screw type oil-free air compressor

The structure of the screw type oil-free air compressor is basically the same as the principle of the oil-injected screw type air compressor, and the air compression is realized by the volume change between the yin and yang rotors and the casing. However, the air circuit and oil circuit of the oil-free screw air compressor are separate.

Screw-type oil-free air compressors are further divided into: water-lubricated screw-type oil-free air compressors and dry-type screw oil-free air compressors.

The main engine of the water-lubricated screw oil-free air compressor and the area it flows through are all stainless steel, and the working process of water is the same as that of lubricating oil. High compression efficiency and low specific power.

When the dry screw oil-free air compressor is in operation, its screw motor rotor compresses the gas through rapid expansion. Resin components are sprayed on the screw of the dry oil-free air compressor to protect the screw from damage during rapid friction. The cooling of the head rotor is accomplished by the rotor cooling jacket located in the casing. The function of the oil circuit is to lubricate the bearings and gears of the air compressor. Between the lubricating chamber and the compression chamber, an effective isolating shaft seal should be used to avoid entry into the working chamber.

Wide range of applications.

Centrifugal oil-free air compressor

There is no doubt that centrifugal air compressors are oil-free air compressors. The whole process of suction compression does not come into contact with oil, so centrifugal air compressors belong to oil-free air compressors.

Centrifugal air compressors are large-displacement air compressors, and are mostly used in factories or enterprises with large gas consumption, such as large-scale electronics factories, large-scale food processing factories, etc. Due to its high speed, high precision and high reliability mechanical properties, it is necessary to require professionals to maintain it regularly, and the cost of consumption will be relatively high.

Oil-free piston air compressor

The oil-free piston compressor belongs to the reciprocating air compressor. Its working principle is the same as that of the oil-filled piston air compressor. One of the differences is that there is no air compressor oil in the crankcase. The second difference is that the surface of the piston is also There is a coating. The power of this kind of air compressor is generally relatively small, and the cylinder cooling is generally air-cooled, which is mostly used for on-board air compressors on buses.

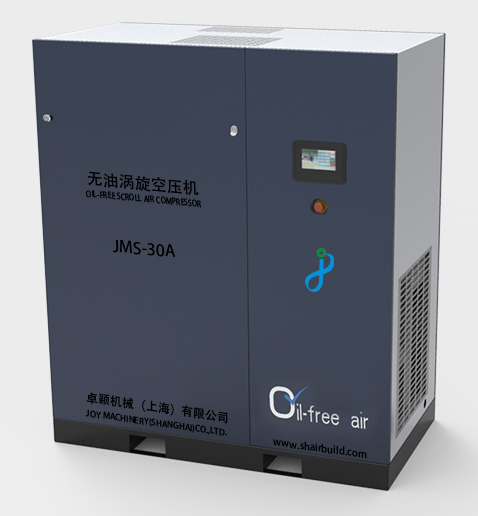

Oil-free scroll air compressor

The oil-free scroll compressor forms several pairs of crescent-shaped closed compression chambers by the meshing of the moving and stationary scrolls, and compresses the gas with the rotation of the moving disks. Smooth operation and low noise.

Oil-free scrolls are generally small in power, low in maintenance costs, and low in gas production. They are mostly used in food, medicine, electronics, and precision spraying.

The oil-free air compressor is a kind of air compressor with good performance. The demand for oil-free air compressors in different fields will also vary, which can be selected according to the production and manufacturing conditions.

JOY Machinery (Shanghai) Co., Ltd. has a professional design team with rich experience and welcomes customization. Diversified products can meet most applications and meet your one-stop shopping needs. The air compressor series includes power frequency screw air compressors, variable frequency screw air compressors, permanent magnet variable frequency screw air compressors, two-stage compression screw air compressors, integrated screw air compressors, laser cutting air compressors, medium and high pressure air compressors Air compressors, oil-free water-lubricated screw air compressors (special oil-free screw air compressors for the medical industry), diesel-moving screw air compressors, electric-moving screw air compressors and other products.

"Customer satisfaction is our unswerving pursuit", "high-quality, good services", and strive to make every customer use the good products they like.

For more information about our products, please visit: www.shairbuild.com , 24-hour hotline: 13621925718 (WeChat, WhatsApp).